Wacker PT2, PT3, PT4, PT6 Troubleshooting - Won't Pump, Won't Suck

Posted by David Schatz - Owner - DHS Equipment on Nov 22nd 2017

We recently filmed a how-to video on troubleshooting and rebuilding the Wacker PT3 trash pump. This blog post is a follow-up to that video, which includes more information and helpful diagrams.

The Wacker PT2, PT3, PT4, and PT6 trash pumps are designed for dewatering of excavation sites, utility vaults, retention ponds, and barge holds. The trash pump is designed to move water with minor debris. However, constant movement of debris can cause premature wear on internal components.

It's important and recommended by Wacker, that you clean the inside of the pump housing after every use. While you are cleaning out the pump housing, you should also check the impeller and volute insert for wear. Use caution while cleaning out the pump housing. The impeller may become sharp from being worn by debris.

While our video covers how to test and rebuild the PT3 trash pump, it doesn't comprehensively cover every troubleshooting diagnoses. Below are Wacker's recommended troubleshooting suggestions:

Pump does not take in water:

- Not enough priming water in housing.

- Engine speed too low. Adjust speed.

- Strainer plugged. Clean strainer.

- Suction hose damaged. Replace or repair hose.

- Air leak at suction port. Check that fittings are tight and housing cover O-rings are sealing properly.

- Pump too high above water.

- Debris collecting in pump housing. Clean pump housing.

- Too much clearance between impeller and insert.

Pump takes in water, little or no discharge:

- Engine speed too low. Adjust speed.

- Suction strainer partially plugged. Clean strainer.

- Impeller worn. Adjust clearance by adding shims or replace impeller.

- Volute insert worn or damaged. Adjust clearance or replace insert.

Suction hose leaks at inlet:

- Clamps are not sealing properly. Tighten, replace, or add clamp.

- Hose diameter is too large.

- Hose is damaged.

Discharge hose does not stay on coupling:

- Pressure may be too high for clamps being used. Add another clamp.

- Hose kinked or end blocked. Check hose.

Impeller does not turn; pump is hard to start:

- Impeller jammed or blocked. Open pump cover and clean dirt and debris from inside of pump housing.

- Impeller and insert binding. Adjust clearance by removing shim from behind insert.

Testing your trash pump:

In order to ensure maximum efficiency from your trash pump, it's important to know how to test your pump properly. (Note: The following specifications pertain only to the PT3 trash pump. Please contact us for specifications for the PT2, PT4, and PT6.)

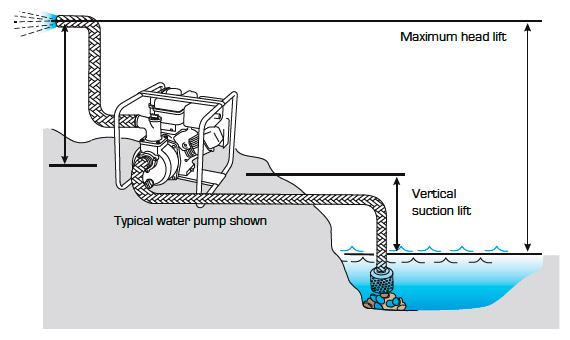

We sell a pump vacuum test gauge that will help you properly test the suction of your trash pump. Vacuum is measured by inches of mercury. One inch of mercury equals one foot of suction lift. The PT3 trash pump has a maximum suction lift of 25 feet. The vacuum gauge should read 25hg (25" mercury) for 25 feet of suction lift.

25hg (25" Mercury) = 25ft Suction Lift

To test the discharge side of the trash pump, all you need is a simple PSI gauge. A liquid-filled gauge would give you the most accurate reading. Discharge pressure is measured in PSI. One PSI equals 2.3 feet of delivery height. 95 feet is the maximum discharge at 41 PSI.

95 / 2.3 = 41 PSI

If you find that your trash pump has worn components that is causing poor performance, the best option is to use our PT3 pump rebuild kit, which includes all of the parts necessary to tune your pump into OEM specifications. Our DHS Equipment PT3 kit includes all of the necessary o-rings, shims, and seals, as well as a new flapper, impeller, volute insert and hardware. For $185.00, this kit is an affordable fix for a poorly performing pump.

If you have questions about our pump kit, please feel free to call us at 866-611-9369.

Author: David Schatz

David Schatz is the founder of DHS Equipment and a technical content expert in light construction equipment, small engines, and professional-grade replacement parts. With more than 30 years of hands-on experience servicing concrete saws, generators, water pumps, and plate compactors, he helps contractors, rental fleets, and serious DIY users keep their equipment running safely and efficiently.

Through practical, no-nonsense articles, step-by-step guides, and maintenance tips, David focuses on real-world troubleshooting, small engine repair, and clear recommendations on OEM and high-quality aftermarket replacement components that reduce downtime, extend equipment life, and improve job site productivity.