How-to: Wacker WP1540 & WP1550 Belt Replacement

Posted by David Schatz, Owner - DHS Equipment on Mar 30th 2017

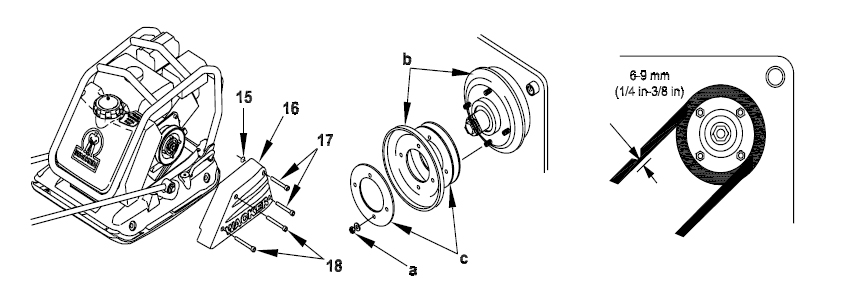

The drive belt on the Wacker WP1540 and WP1550 should be inspected every 2 weeks or after every 50 hours of operation. Proper deflection of the drive belt is between 1/4"-3/8", halfway between the pulleys. If you have more than 3/8" deflection, check your shockmounts for wear or damage before adjusting the clutch or replacing the drive belt.

Removal:

- Pivot guide handle forward

- Remove screws (17 and 18) to remove beltguard (16). O-rings (15) will remain on screws, and keep screws captive in the belt guard

- Remove four nuts (a) and lock washers holding pulley halves (b) and spacers (c) together

- Remove outer pulley half to remove drive belt from exciter pulley and machine

Installation:

- Install belt on exciter pulley

- Install three spacers (c) and outer pulley half with belt between pulley halves (b)

- Install lock washers and nuts (a). Tighten nuts securely

- Pivot guide handle rearward to operating position

Adjustment:

- After the first 20 hours of use, check belt deflection. Drive belt deflection should be 6–9 mm (1/4 to 3/8 in.) half way between the clutch pulley and the exciter pulley

- Two or three spacers with new factory belts should provide the correct tension

To increase belt tension (reduce amount of deflection):

- Remove nuts (a) and lock washers. Remove outer pulley half and one spacer

- Install outer pulley half, then the unused spacer. Secure with lock washers and nuts (a)

- Check belt deflection again. If necessary, remove another spacer from between pulley halves and put outside of pulley halves

- Install belt guard